My thanks to Oztules, David and other's for a excellent documentation.

wanting to build the zapper but with modification to control max voltage before discharge, i simulated the circuit using LTSpice

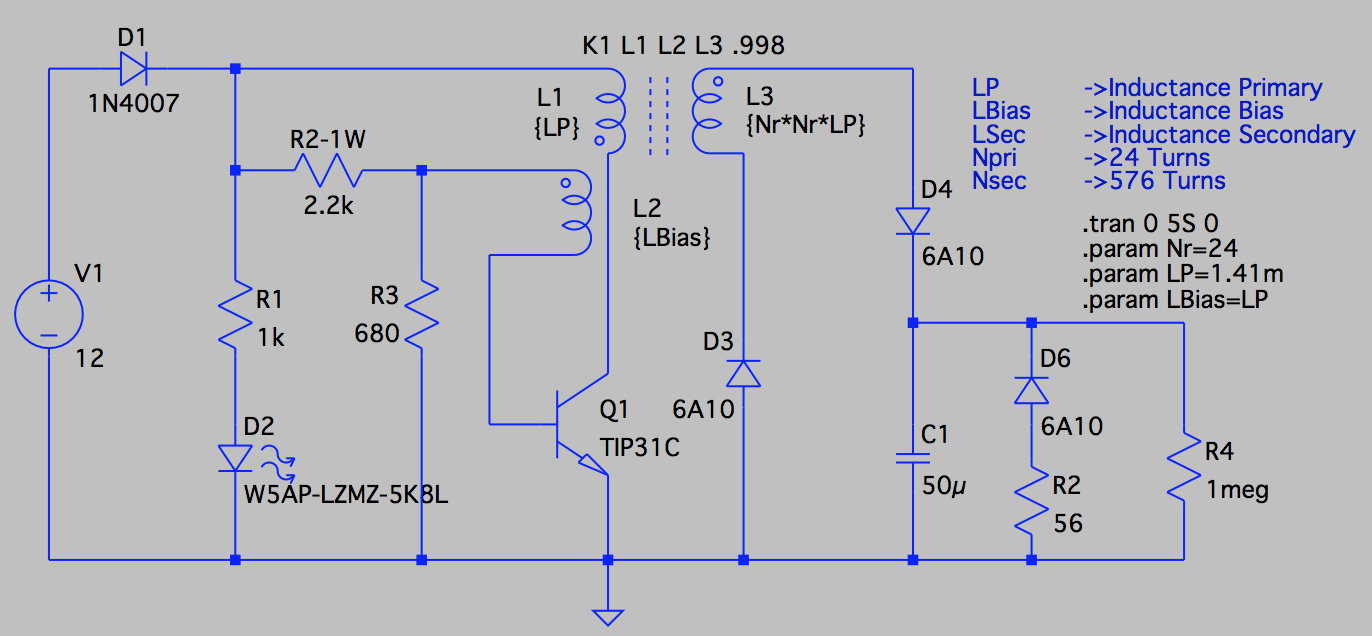

the schematic without the output stage, only Inverter 12VDC to 600VDC

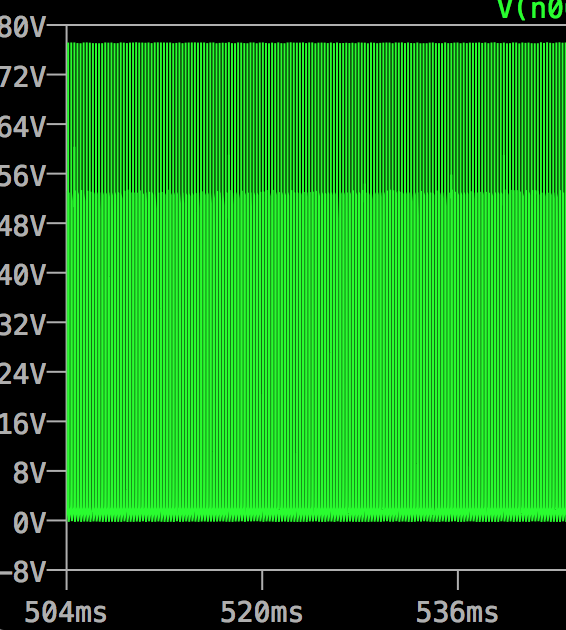

the output Voltage

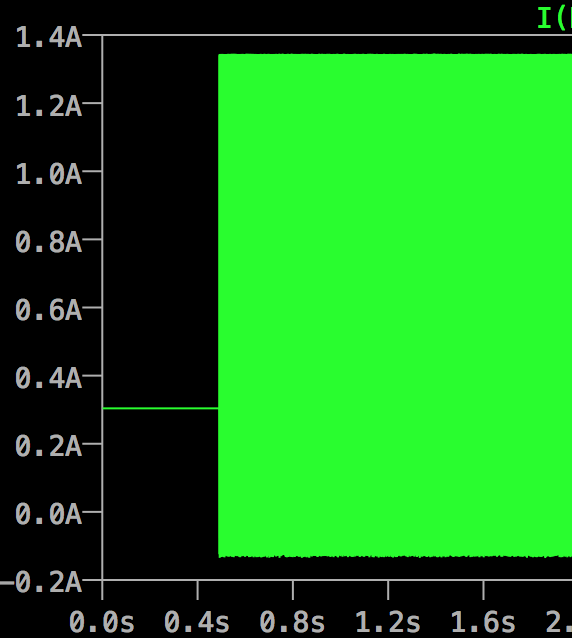

without the Cap the Output is 1KV and with the Cap the voltage reaches 1KV after long time for the 50uFD it takes 3,18 Sec to reach 600V with the Value of R2->2K2 and R3->680.

The Primary inductance is a calculated value (

http://powermagnetics.co.uk/calculator) with AL for E34 to be 2440 and AL for E49 = 3700 (without Gap) from datasheet (

http://www.feryster.com/polski/e349.php?lang=en) = 1.41mH and for E49 its calc to 2.1mH. The simulation is using turn ratio of 24 the Secondary Turns is 576 Turns (min 400 max 600 as per design Notes).

if i could get some help, it would be great

1. What is the measured value of L Primary 24 Turns on E34 & for E49. (without Gap..? hope this is also true)

2. Simulation show the Voltage across Cap is 600V @ 3.18 Sec ..? But the Fence Zapper is to Pulse every 1Sec and Diac breakdown is 600V..? hence in the simulation the trigger to the Triac would happen once every 3.18Sec and not 1Sec.

If the Inductance is available, maybe the simulation would be more accurate..? else If I would be the exact Period of the pulse I could trial n error to get the Inductance to match the period.

@ Oztules,

a) in the posting you mention that the R2 / R3 should be lowered for faster charge of the Cap. would you kindly inform do I decrease the R2 (2k2) or the R3 (680).? which is a better option.

b) the current in D1 1N4007 is 1.34Amps.. which is greater than 1Amp Peak rating of the diode, but I guess because its pulses, this should not be a problem..? or should the diode be changed.

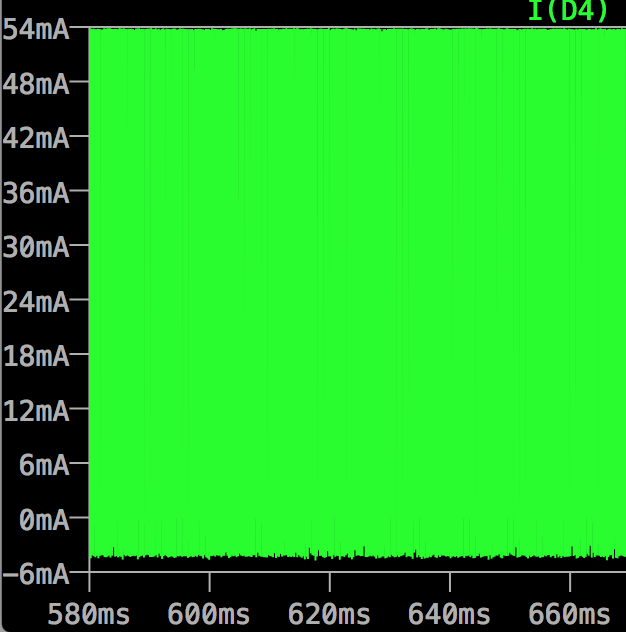

c) both the D4 & D3 the max current is 54mA hence David PCB with 6Amp Diode is not necessary and the IN4007 would do the job..?

d) the Power in Q1 TIP31 peaks at 48W.. is this normal.. and the CE voltage is 77V which is below the Vce of 100V for TIP31C but above 60V for TIP31A ..?

Thanks in Advance..

Regards

Srikanth Kamath

http://tskamath.pactindia.com