Over the course of the first winter in the van, I discovered some of the art of dealing with thermodynamics involved preventing cold air pooling. Things were very exaggerated in there as the height of the space was only around 4 ft or so. In the truck, the height may be 50% more, and the effect not quite as pronounced, but it's still there. I thought this deserved it's own 15 minutes of fame, as it's complicated and can be difficult to work out what's happening and why.

There are two ways to look at the effects and behaviors of the layers that form naturally when a gradient forms. When you're heating a space, the difference between the inside and outside temps have varied results depending on what they are. Generally, the colder the air outside, the greater the tendency for drafts to form, and the greater the gradient inside if the air is allowed to stagnate.

This can be exploited, on one side of the coin, to reduce the amount of fuel needed to reach a comfortable level, if you're doing something similar to what I am for my winter sleeping situation. If you're raised up and only sharing the space where the heat wants to go (eg, "Granny's Attic"), allowing the cold air to pool down below during the night can save you a noticeable amount of fuel. The less surface area the warmer air shares in common with the colder outside air, the less the gradient in those areas, and the less transfer takes place.

Looking at it from the other side of the coin, this presents a problem when you go to get up in the middle of the night, or if you're lucky enough to not yet be dealing with that, when you go to get up in the morning.

Cold air is heavy, and it's density increases as the temperature goes down. This causes it to be much more resistant to being stirred up, which means more energy is required to make it mix with the warmer air above it. This isn't really a "linear" relationship, either. When the temperature of the warmer air reaches a certain level over the cooler air, something strange happens. The cold air begins to set up a hard boundary down around the 1/4 - 1/3 point above the floor, and becomes much more resistant to mixing. I liken it to putting a shop vac up on the roof, and running the hose down into a swimming pool. While this is an exaggerated analogy, the concept is similar. It doesn't just get lifted up and mix with the warm air, it takes some brute force behind it at that point.

Brute force translates into a lot more power, or getting clever with a bit less power.

This was the proof-of-concept anti-draft and mixing device I came up with for the truck. In the van, I got away with finding the right fan and using the natural shape of the back gate to get the warmer air to head down and mix with the cooler air below. In here, by the time the warm air got to the floor, it had already done quite a bit of mixing, and turbulence had stolen so much power from the stream, that it just wasn't enough. Adding the dryer vent tube to it and guiding it down helped tremendously, but there are problems with this as more than a demonstration. The structure of the tube is such that the ripples in the aluminum cause turbulence in the air inside, stealing energy from the stream just as it did in the open air. By the time the stream gets to the floor, it is much warmer and more intact than just an open fan pointing down, but it's weak and even full out, my most powerful fan was making little more than a useful flow across the floor for mixing. It was effective enough, but there had to be a more efficient way to get the air down. I was more or less prepared to accept that the losses were just going to be a fact of life, and it was what it was. That's what happens when there's too much going on...

In the spirit of giving credit where it's due, DaveW threw the concept out there that formed the basis for what finally came out the other end. While in hindsight it's almost a "Duh!" moment, I sure wasn't seeing it - That's what all this is for tho right? Thanks goes to Dave for getting me thinking "back inside the box"

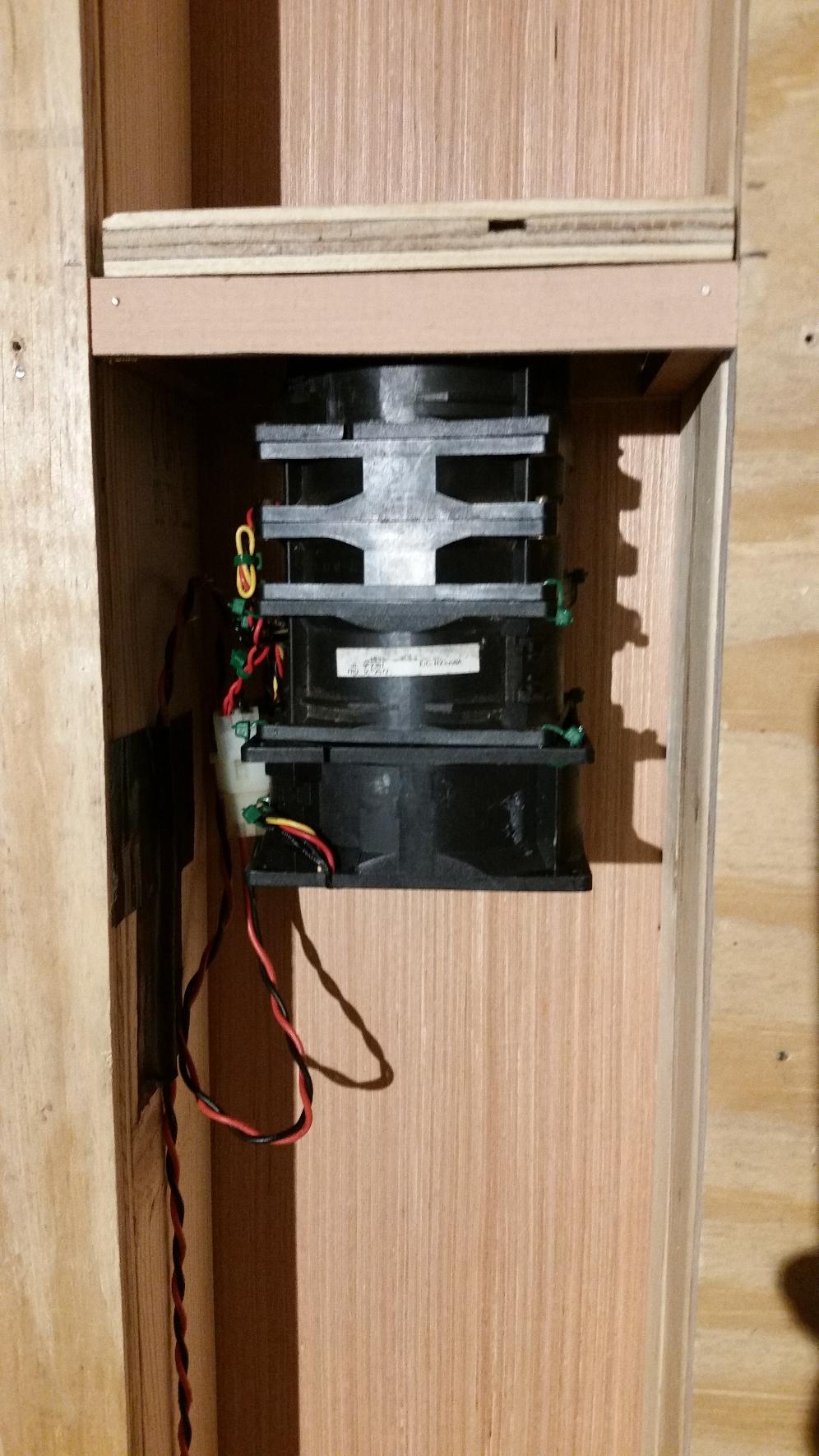

This is where it sits right at the moment. The bottom was left open so as to be able to experiment with various "nozzle" shapes, dimensions, and forms. The top is just missing a bezel that holds the bottom of the filter in place and puts pressure on the fan baffle to prevent rattling and such without needing to screw it into place. I'll post the final result when it's all said and done, but for now, I think most will be able to catch on to how this works.

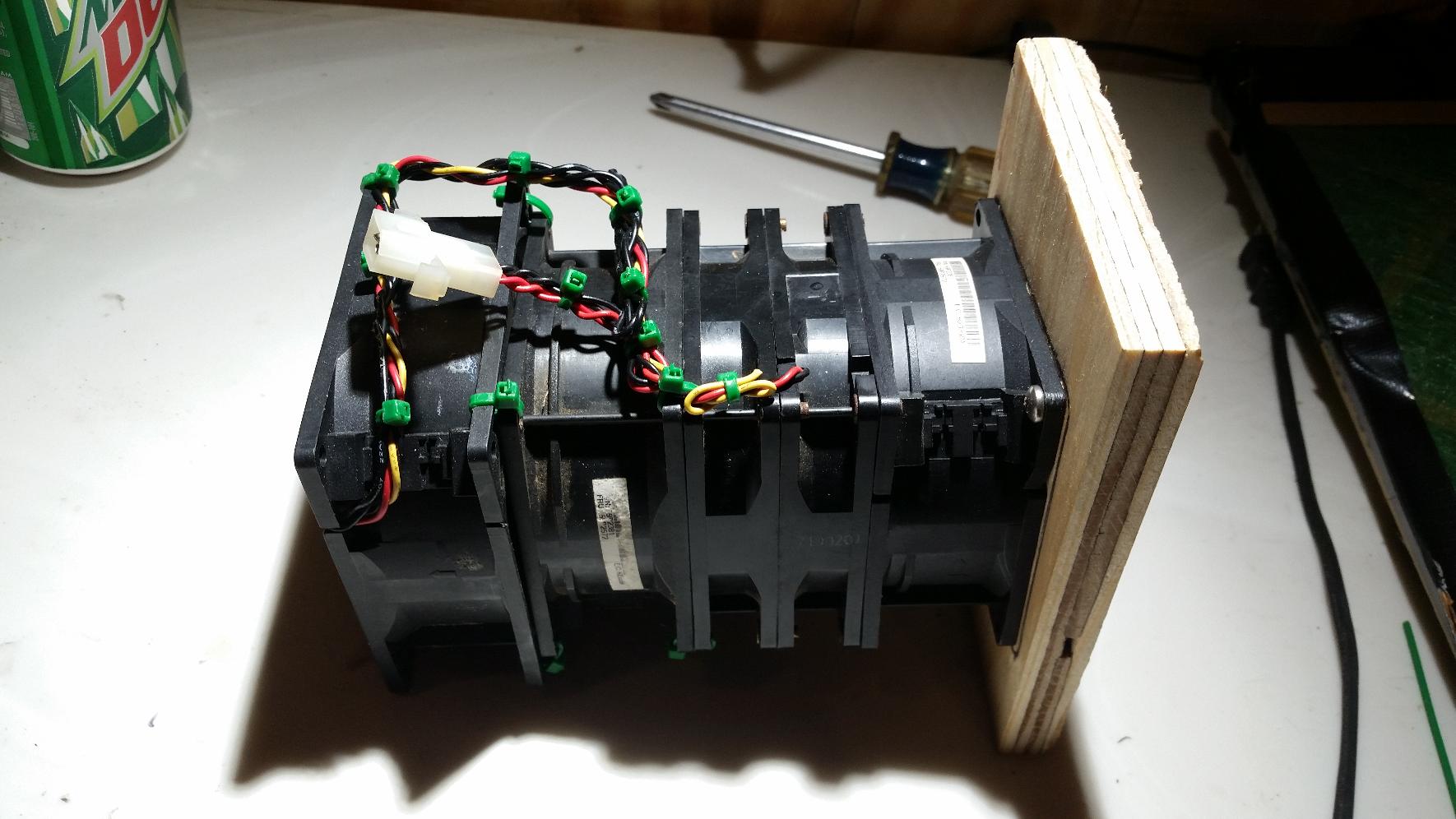

True to MadScientist267 form, this what I came up with for the prime mover for this whole thing. There are two fans there, separated by shells from old fans that had broken blades, dead bearings, and so on.

At the intake is an 80mm case fan. For anyone that may be looking to reproduce this project using similar items, I should note that all case fans are not created equal. I dug thru the stash until I found one that was stronger than the others, and this one fits that bill nicely. I don't know exact specs on it, but it isn't afraid to throw a little more air than many. PC techs will know what I'm talking about here.

At the other end is a 100mm, 3 blade, "deep dish" fan. These things are awesome on their own, and came from some decommisioned IBM server hardware. They do make a little bit of noise when spooled all out, but the little bit of noise is worth it for something like this. The combination is such that they won't need to run full out the majority of the time, and calm down nicely when tamed with a buck converter. Eventually, these will be controlled with a continuously variable differential thermostat. Basically, this is just a fancy way of saying that instead of cycling on and off, the temperature difference between the floor and ceiling determines how fast they run. Again, I'll post the details on that when I get to that point. Rest assured, it's not as complicated as it sounds.

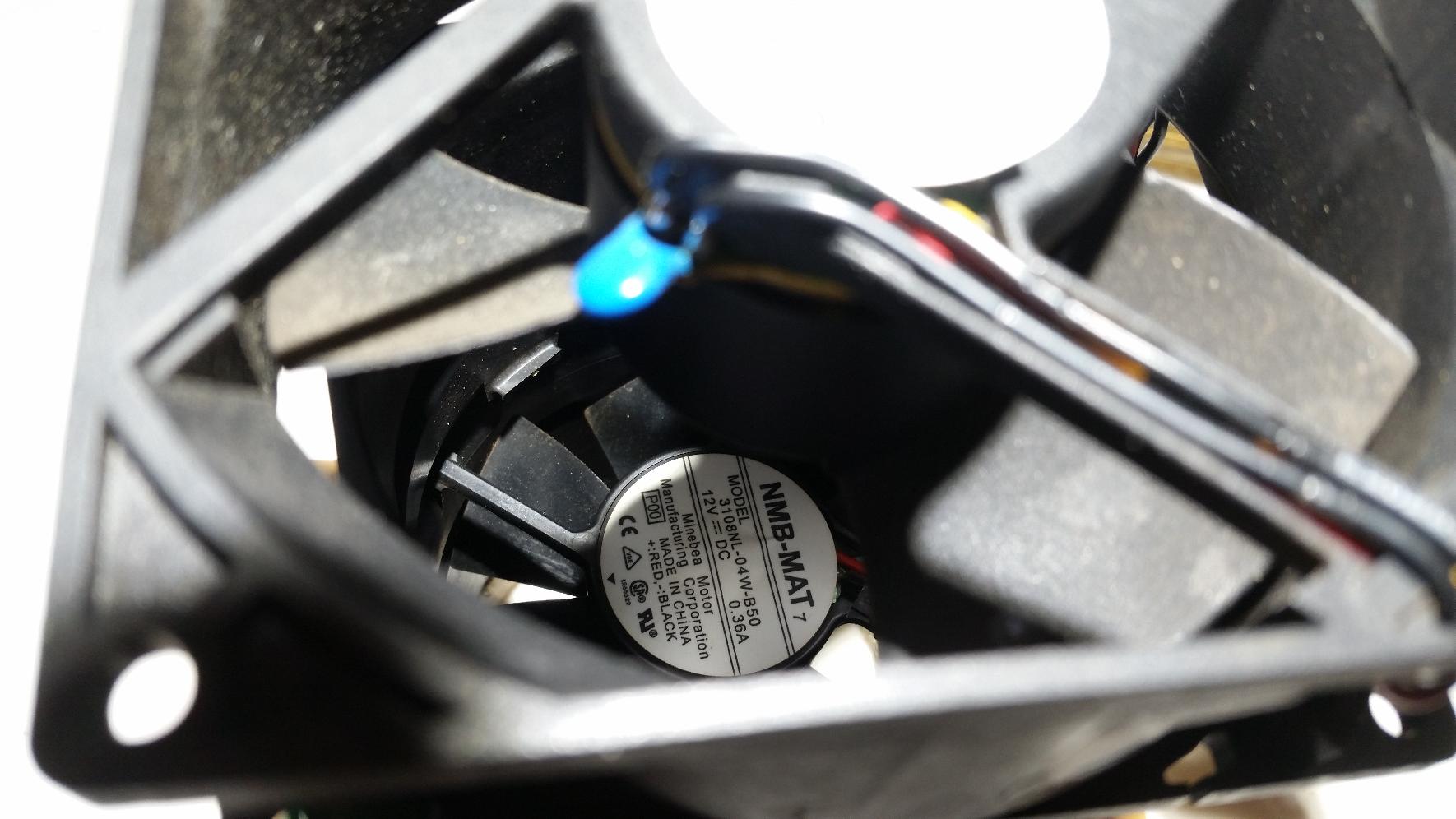

Peering down into the guts of the assembly, a very important property of the design becomes apparent... The fans are counter-rotating. Air tends to be spinning somewhat when it exits a fan, in the direction of the rotation of the blades. When two fans that rotate the same direction are added together in this manner, the boost effect is minimal, because the blades of the second fan are trying to grab air that's already spinning in the direction that it is. Counter-rotation allows the second fan to more or less be able to "cut thru" the spinning air, effectively increasing the speed of the second fan. The result is more flow and a higher backpressure in the plenum below.

Up on the wall, the fan assembly slips down onto a set of stops that hold it in place behind and below the air filter. Nothing super magical about this, just need to be able to retrieve the assembly should a fan die. A dead fan has the effect of virtually crippling the remaining working fan, so you'd want to be able to address this as easily and quickly as possible when it's cold. Needless to say, keep a spare around if you can, fans never fail, right?

The fan assembly, before insertion, and an "x-ray" view

Continued . . .