I'll explain the post later

EDIT -

I have problems posting with the phone now after an update, and its unpredictable. Sometimes it wants to cooperate halfway decent, other times just getting a sentence out is a very painful process. Right now, its behaving, so here's the explanation, as promised:

I've rebuilt the flyback driver, as a short time ago, the buck boost module I was using to dial it in got a bit on the warm side, and I ended up fusing one of the schottky diodes on it. Result was, I could still buck, but couldn't boost, and it was drawing a LOT of extra power. So I ditched it.

I had settled on about 18V for the supply for the driver before this happened however, and have a few old 19V laptop bricks laying around, and so just decided to use one of those. To protect it, and reduce EMI, I built a small filter based around a counterwound inductor like those commonly found in AC filters. It worked fine as far as filtration, but the output cap was getting extremely hot (uncomfortable for even me to touch, and I am known to be able to keep fingers on hot objects long after most let go). I decided I had to do something before it vented and left me with yet something else to deal with. The driver had also become very unstable even though the output cap was more than twice the capacity of the one on the buck boost.

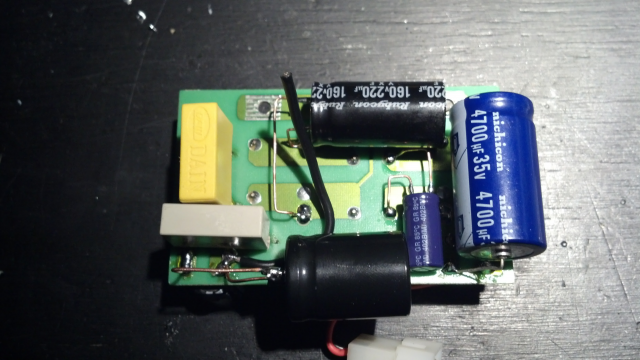

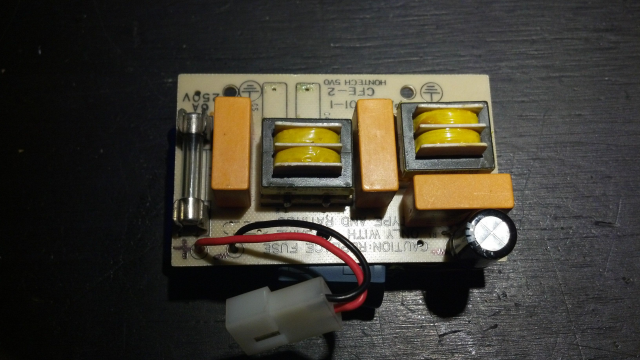

What I came up with centered around the same concept as the first filter, but is much more robust. Overkill even. There are now 2 counterwound inductors, and a myriad of both electrolytic and X2 pulse rated caps to deal with the mayhem this device presents to the supply rail.

The backside of the new filter. The basic filter came from an ancient XT PC power supply, as it was constructed on its own board, and had all the baseline requirements already in place. I simply expanded on it. The unmarked cap at the bottom is a 330uF 200V main filter cap for switching supplies, it still warms up just a touch, but is in no danger of letting the smoke out. The caps go down progressively in voltage and up in capacitance as they get further toward the input of the filter. All of the others run cool.

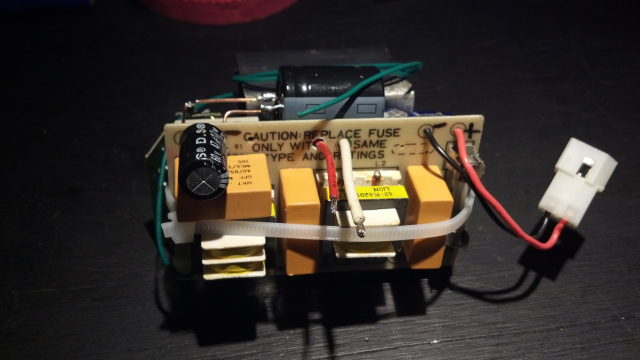

Another shot.

And another...

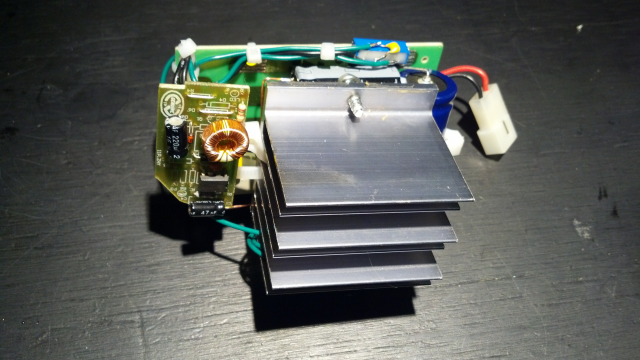

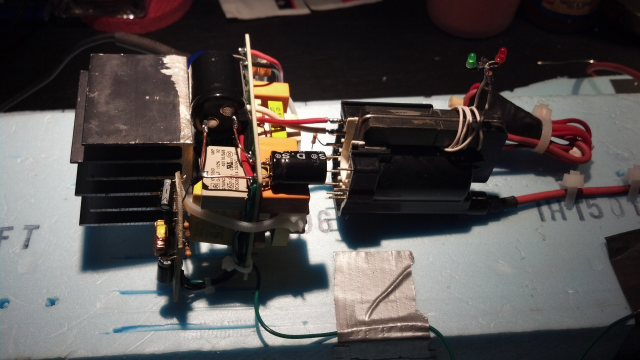

Here the driver is essentially assembled, without the flyback attached.

The assembled driver with the flyback connected. I tamed it down a bit - many of the pots have been replaced with fixed resistors, and the only pot that remains controls the gate drive on the MOSFET.

The increase in performance was astounding after the redesign... I could pull 3 inch sparks before I did some further adjusting on the fixed resistors, its now down to an inch again at full throttle. Even this is proving to be a bit intense.

Also, I made it a point to ensure that it cannot draw a hot arc any longer. The gun will eventually be enclosed, and fires are never a good thing, but only get worse in small spaces!

The master fuse for the original supply was also on the filter, and is removable. Its currently 6A but doesn't need to be any more than 3A to protect everything. I'll be swapping that out soon.

Steve