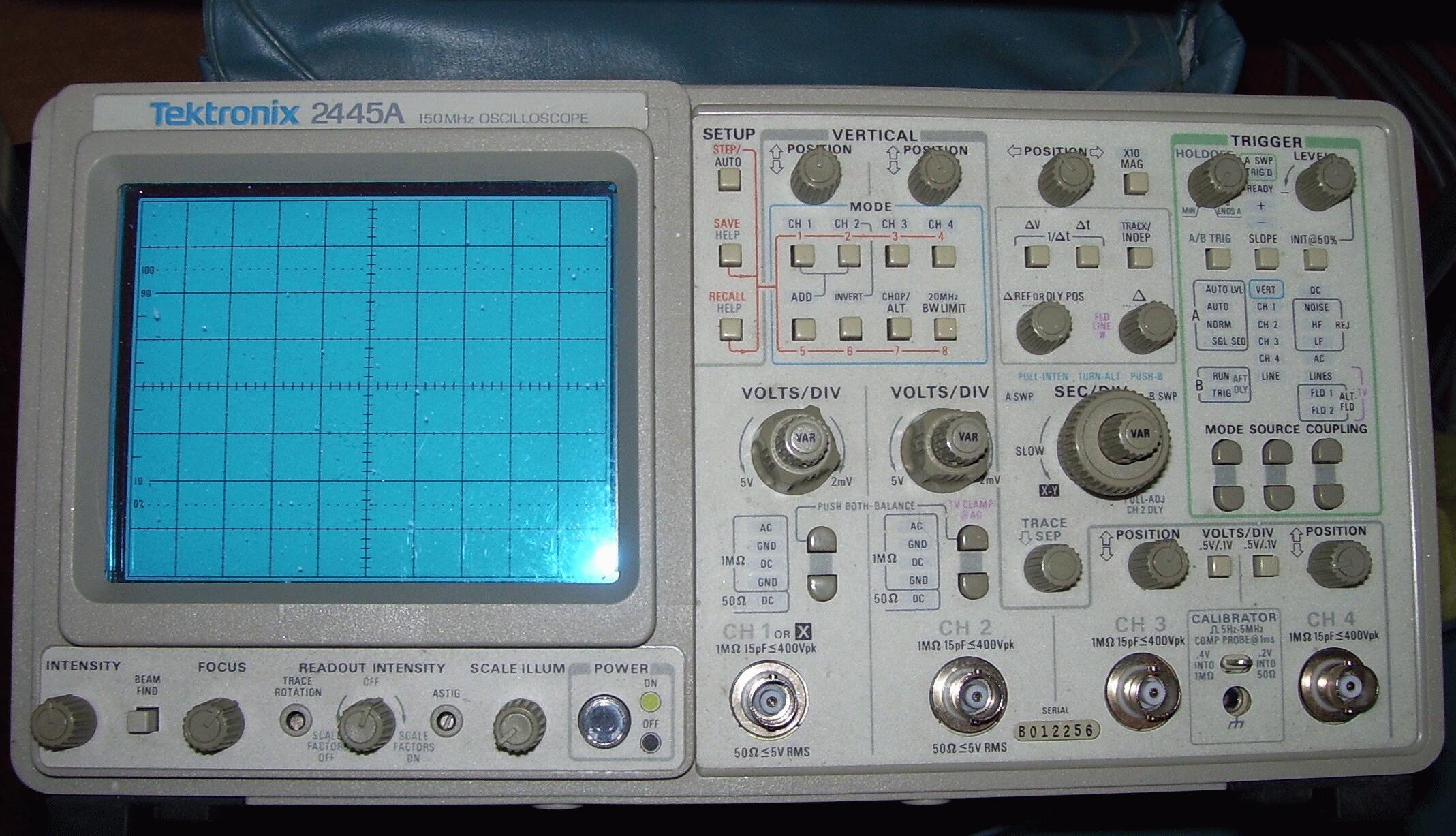

Hi, the new used oscilloscope arrived. It displays the calibration wave form on each channel. What connections are needed to view the AC output of the PMA?

Ahh, posting on both.... thats fine, I'd far rather respond here anyway. We don't have so many argumentative ignoramuses

I've got a similar scope - couple of models up I think, the Tek 2445.

If you connect ONLY ONE CHANNEL with the input of that channel set to DC (not AC, reason later), and clip your input lead across any one coil (that's any two phase wires if they're in delta, or any phase and the star point in star/wye), you should see one phase (one of the three).

DO NOT CONNECT MORE THAN ONE CHANNEL AT THIS TIME, because you will find that all channels "ground" is the same. Putting more than one channel on, will very likely let out magic smoke. ALSO, CHECK FIRST that your 'scope ground doesn't have any potential to your generator output - star point or whichever phase you wish to use for the earth. If it does, you will need an isolating transformer for the scope.

In the absence of a suitable transformer, you MAY get away with using a suitable voltage, AC-rated capacitor in series with the ground lead of your scopes input. Around 2.2uF 630V would be a good place to start.

Edit: I forgot. The reason for DC not AC is that your input signal could be fairly low frequency, and the AC coupled input on the scope will affect how it displays your signal. It may not display it at all, whereas the DC coupling will show you exactly what's going on, including any DC offset.